Department of mechanical Engineering

VISION

MISSION

2. To provide students and faculty members with opportunities for professional development and support in research, innovation, and entrepreneurship.

3. To provide a supportive learning environment through well qualified faculty members and state-of-the-art laboratories that encourage students to think critically and creatively, and to engage in real-world problem-solving.

VISION

2. To provide students and faculty members with opportunities for professional development and support in research, innovation, and entrepreneurship.

3. To provide a supportive learning environment through well qualified faculty members and state-of-the-art laboratories that encourage students to think critically and creatively, and to engage in real-world problem-solving.

PROGRAM OUTCOMES (POs)

1. Engineering Knowledge

Apply the knowledge of mathematics, science, engineering fundamentals, and an engineering specialization to the solution of complex engineering problems.

2. Problem analysis

3. Design/ Development of Solutions

4. Conduct investigations of complex problems

Use research-based knowledge and research methods including design of experiments, analysis and interpretation of data, and synthesis of the information to provide valid conclusions.

5. Modern Tool Usage

Create, select, and apply appropriate techniques, resources, and modern engineering and IT tools including prediction and modelling to complex engineering activities with an understanding of the limitations.

6. The Engineer and Society

7. Environment and Sustainability

Understand the impact of the professional engineering solutions in societal and environmental contexts, and demonstrate the knowledge of, and need for sustainable development.

8. Ethics

Apply ethical principles and commit to professional ethics and responsibilities and norms of the engineering practice.

9. Individual and Team Work

Function effectively as an individual, and as a member or leader in diverse teams, and in multidisciplinary settings.

10. Communication

11. Project Management and Finance

Demonstrate knowledge and understanding of the engineering and management principles and apply these to one’s own work, as a member and leader in a team, to manage projects and in multidisciplinary environments.

12. Life-long learning

Program Specific Outcomes (PSOs):

1. Professional Skills: To equip students with a wide range of technical, professional and transferable skills those are essential for a successful career in the mechanical engineering industry, such as design and analysis, manufacturing, and project management.

2. Problem Solving Skills: To develop students’ ability to identify, analyze, and solve complex mechanical engineering problems by using appropriate mathematical and computational tools, as well as hands-on experimentation and design experiences.

3. Successful Career and Entrepreneurship: To prepare students for a successful career in the mechanical engineering industry, either as employees or as entrepreneurs by providing them with opportunities to apply their skills in real-world scenarios and to network with industry professionals.

COURSE OUTCOMES (COs)

Bachelor of Engineering

2022 Scheme

Mechanical Engineering

2021 Scheme

Mechanical Engineering

2018 Scheme

Mechanical Engineering

COURSE OUTCOMES (COs)

Postgraduate Engineering

2022 Scheme

Mechanical Engineering

2020 Scheme

Mechanical Engineering

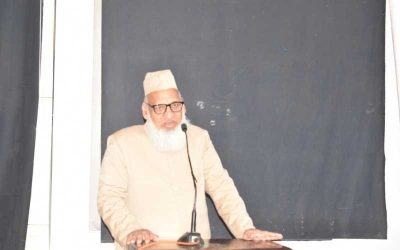

A very warm welcome to the Department of Mechanical Engineering, Bearys Institute of Technology, Mangalore, India. Mechanical Engineering popularly known as “Royal Mech” is one of the oldest and evergreen branch of engineering. Mechanical Engineering was established in the year 2010 with an intake of 60 students. The department is currently headed by Dr.Vasantha Kumar and the department has well qualified and highly experienced dedicated teaching faculty members. The department has achieved academic milestones by achieving 02 University Ranks. The department is proud to say that Mr.Mohiuddin A.G student of 2020 batch has got 7th rank in VTU Examination.

Our Faculty

Dr. Vasantha Kumar

Teaching Exp. – 13 years,

Industry Exp. – 1 year,

Research Exp. – 5 Years.

Mr. Arvind Kumar

Teaching Exp. – 13 years.

Dr. Imran Mokashi

Teaching Exp. – 13 years,

Industry Exp. – 2 years,

Research Exp. – 2 year.

Mr. Manjunath Ichchangi

Teaching Exp. – 11 years,

Industry Exp. – 2.5 years.

Dr. Mohamed Kafeel Delvi

Teaching Exp. – 12 years.

Mr. Gokuldas M

Teaching Exp. – 11 years.

Prof. Prithviraj M

Teaching Exp. – 8 years.

Dr. Sandeep Nambiar S

Teaching Exp. – 10 Months

Research Exp. – 4 Years

Technical Staff

Mr. Clement Varthika

Experience: 18 Years

Mr. Abdul Sathar

Experience: 23 years

Mr. Bharathraj

Experience: 1 Year

Publications

Workshop/FDP/Conferences attended

Grants Received

Research Supervisors and Research Scholars

1. CAED and CAMD laboratory

Students will be exposed to advanced technical graphics. The laboratory is equipped with the latest high tech graphics producing computers. These computers are loaded with the latest 2D and 3D graphics software packages.

Students will be trained in CAD/solid edge Programs ranging from beginner to advance in mechanical and engineering design. Students will be exposed to descriptive geometry applications such as folding line relationships and notations, angles between plane revolutions and intersections. Also, students will be exposed to solid modeling of mechanical components and assemblies.

2. Forging and Foundry Laboratory

The forging and foundry Lab acquaints students with the practical aspects of manufacturing processes. Laboratory experiments helps a student to gain knowledge and expertise in diverse areas such as sand technology, tooling and methoding, casting parameter of ferrous & non-ferrous metals, modern casting process in the field of foundry. In forge technology the students are exposed to die design, forging parameter of ferrous & non-ferrous metals and recent developments in forging etc.

3. Material Testing Laboratory

This laboratory is well established and used to determine the physical and mechanical properties of raw materials and components from steel to composites and ceramics. Currently, this laboratory equipped with universal testing machine, impact testing machine, torsion testing machine, fatigue machine and hardness testing machine.

4. Basic Workshop

The basic need of engineering workshop is to provide theoretical and practical knowledge of manufacturing environment to all the engineering students. Therefore, an attempt has been made through this laboratory subject to learn both the theoretical and practical knowledge of shaping a product. This Basic Workshop laboratory classes covers most of the basic skill that an engineering students needs to familiarize themselves.

Carpentry Shop: Carpentry shop deals with making joints for a variety of applications like door frames, cabinet making furniture, packing etc.

Fitting Shop: The fitting shop is related to assembly of parts, after bringing the dimension or shape to the required size or form, in order to secure the necessary fit.

Welding Shop: In welding shop, an engineering student learns the art of joining similar metals by the application of heat, with or without application of pressure or filler metal.

5. Machine Shop (w/s)

The Machine Shop is dedicated to taking the theoretical knowledge learned in a classroom environment and applying it to real world tactile solutions. The shop contains a spectrum of equipment and technology ranging from simple hand tools and measuring equipment to shaping machine, milling machine and lathes.

The Machine Shop Laboratory provides hands-on experience with the basic machining techniques and types of equipment in manufacturing environments. This includes turning operations, drilling, boring, basic milling, surface grinding, sheet metal shearing and bending, basic welding and the use of layout and precision measuring tools common to machine shop environments.

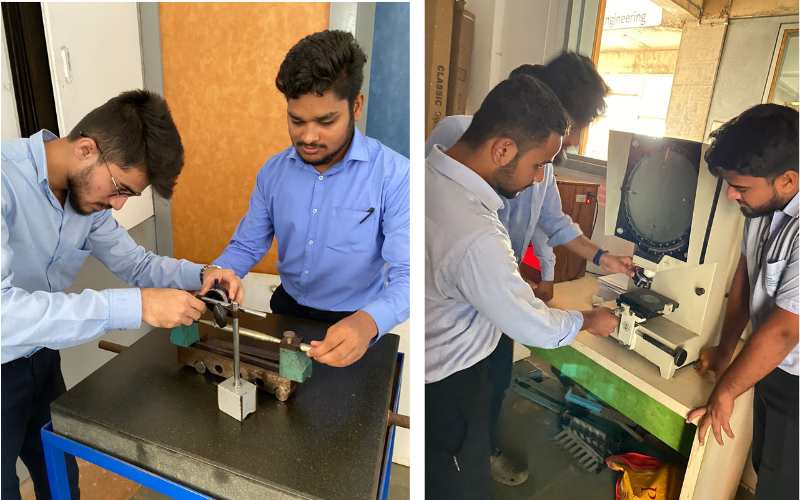

6. Mechanical Measurements and Metrology Laboratory

Measurements & Metrology Laboratory is a well equipped laboratory which provides ideas on hands on experience with various measuring instruments to utilize in industries. on evaluating mechanical properties of a given specimen or structure. Apart from curriculum, some additional experimental setups are there which helps the students to enhance their knowledge. Students also get opportunity to implement their ideas through various application oriented micro projects.

7. Fluid Mechanics and Hydraulic Machines Laboratory

The fluid mechanics laboratory is designed to examine the properties of fluids and to conduct experiments involving both incompressible and compressible flow. The Hydraulics Laboratory is a state-of-the art facility used to conduct a variety of experiments pertaining to water. These studies provide fundamentals knowledge on design of pumps, canal and hydraulic turbine and carry out their performance study useful for(in) hydel power plants.

8. Energy Conversion Laboratory

This lab will help students to see how energy can be converted from one form to another. Students will observe the loss in useful energy as a result of such a conversion and measure the efficiency of the engine. Students also conduct the experiment to find out the flash point, fire point and calorific values of the fuels. This laboratory is facilitated with four stroke single cylinder diesel engine, Two stroke single cylinder petrol engine, Four stroke single cylinder variable compression ratio engine, Morse test, Boy’s gas calorimeter, Redwoods viscometer, Say bolt viscometer, Valve timing diagram (four stroke single cylinder diesel engine), port timing diagram (two stroke petrol engine), Abel Pensky and Marten’s apparatus and Cleveland’s apparatus.

9. Heat Transfer Laboratory

Heat Transfer Laboratory helps the students to understand the basic concepts of heat transfer: Conduction, Convection and Radiation which are the three basic modes for heat transfer to take place. To enhance the practical knowledge of industrial equipments, students perform experiments on some common heat transfer equipments such as thermal conductivity of metal rod, composite wall apparatus, parallel flow and counter flow heat exchanger, Emissivity measurement, Stefan Boltzmann apparatus, Free or natural convection, Forced convection, Heat transfer through fin pin, Vapor compression refrigeration test rig and Transient conduction heat transfer.

10. CIM and CAMA Laboratory

The laboratory is established to provide our students with the knowledge and hands on experience in computer integrated manufacturing segment. The objective of the CIM laboratory is to prepare the students industry ready and to acquire employability skills with the CNC programming and cutting tool path generation through CNC simulation software by using G-codes and M-codes. In addition, it is aimed at demonstrating and understanding the importance of automation and predominant role in the assembly line of the shop floor, so that the need for agile manufacturing to meet the urging need for the global competitiveness of upcoming industries.

11. Design Laboratory

It facilitate hands-on learning of theory of machines concepts to 7th semester Mechanical UG students. The lab experiments validates the concepts of kinematic, dynamic and design theories of machine components under motion condition. It facilitate hands-on learning of vibration and oscillation concepts of machinery systems to UG students, the lab experiments validates the concepts of vibration under forced and damped condition. Students can be able to validate and extend the theoretical knowledge into practical machine applications.

12. Supersonic Aerodynamics Research Laboratory

In recent years, the ability to predict the behavior of supersonic flow has become increasingly important. The pressures acting on the blunt base of a body in a supersonic flow has become the topic of interest for many researchers in the field of ballistics. Recognising the rapid growth of interest in supersonic drag problem associated with the development of supersonic aircraft, projectiles, missiles and spacecraft, we at Bearys Institute of Technology, Mangalore have designed an experimental facility to study the base drag arising from flow separation behind blunt bases with the help of internal flow through sudden expansion region.

The laboratory is equipped with state of the art equipments like – Electric powered screw type air compressor (volume discharge 55 cfm of air, pressure 138 psi), IE2 TEFC Squirrel cage Induction Motor 11 kW, 400 V, 50Hz, Two mild steel air storage pressure vessels volume 2 m3, pressure 200 psi, A settling chamber with provision for model mounting at the centre with a three dimensional traverse mechanism having six degrees of freedom (3 translational and 3 rotational). The pressure gauge readings are measured using a LABVIEW Data Acquisition System.

EVENTS

BIT Hosts 1st International Online FDP on New-Age Alloys and Composites in Association with VTU, Belagavi

The Department of Mechanical Engineering, Bearys Institute of Technology (BIT), Mangaluru, in association with Visvesvaraya Technological University (VTU), Belagavi, successfully organized a Three-day International Online Faculty Development Program (FDP) titled “New Age Alloys and Composites in the Advent of AI, ML, and 3D Printing” from April 7th to 9th, 2025.

Mechanical Engineering Industrial Visit to KMF Nandini Dairy, Mangalore – 2024-25

The Department of Mechanical Engineering at Bearys Institute of Technology organized an industrial visit to KMF Nandini Dairy, Mangalore, on February 24, 2025, for 17 students accompanied by faculty coordinators Dr. Imran Mokashi, Dr. Mohamed Kafeel Delvi, and Prof. Manjunath Ichchangi.

Two day Workshop on “The Indian Startup and MSME Ecosystem in the Age of AI” Concludes at Bearys Institute of Technology, Mangalore

The Department of Mechanical Engineering, Bearys Institute of Technology (BIT), Mangalore, successfully hosted a two-day workshop on “The Indian Startup and MSME Ecosystem in the Age of AI” on December 4th and 5th, 2024.

Mechanical Engineering Department Organized a Talk on “My Constitution My Pride”

The Department of Mechanical Engineering at Bearys Institute of Technology (BIT), in association with the BIT NSS, organized a Constitution Day event under the theme “My Constitution, My Pride.” on 28th November 2024 at BIT International Seminar Hall.

Inauguration of Mechanical Engineering Students Association (MESA 2K24-25) & Technical Talk

The Department of Mechanical Engineering inaugurated its student forum Mechanical Engineering Students Association – MESA 2024-25 on September 30, 2024 followed by a Technical Talk by Dr. Gnanashekaran Associate Professor Mechanical Engineering NITK, Surathkal.

Mechanical Engineering Industrial Visit to Gurucharan Industries, Bykampady, and Shakthi Industries, Mangalore

Industrial visits provide the students with an opportunity to learn practically through...

Mechanical Engineering Industrial Visit to Government Tool Room and Training Centre (GTTC), Mangalore

Industrial visits provide the students with an opportunity to learn practically through...

The Department of Mechanical Engineering, BIT, Mangalore celebrated “VANAMAHOTSAVA” at Bearys Knowledge Campus

The Mechanical Engineering Students Association (MESA), in collaboration with the NSS Unit of BIT,...

FAREWELL FUNCTION FOR THE BATCH 2020-24

Department of Mechanical Engineering organized a “FAREWELL FUNCTION” for 2020-24 batch students at...

Mechanical Engineering Department Organized Final Year Student PROJECT EXPO-2024

The Department of Mechanical Engineering at Bearys Institute of Technology (BIT) in Mangalore...

BIT, Mechanical Engineering Department Conducted Sports Day “MECHSPO-2K24” for Students and Staff

The Department of Mechanical Engineering successfully conducted Sports day “MECHSPO-2K24” on 7th...

Entrepreneurship, Skill, Attitude, and Behavior Development.

The Department of Mechanical Engineering and the Institutions Innovation Council at BIT hosted a...

Mechanical Engineering Industrial Visit to ECO-BLISS, Bantwal Taluk and DECCAN PlAST Industries, Konaje

An industrial visit offers the students with an opportunity to learn practically through...

Mechanical Engineering Industrial Visit to CAMPCO Chocolate Factory, Puttur

An industrial visit offers the students with an opportunity to learn practically through...

INAGURATION OF MECHANICAL ENGINEERING STUDENTS ASSOCIATION (MESA 2K24) & 2nd YEAR STUDENTS WELCOME

MESA 2K24 (Mechanical Engineering Students Association) is a student forum of Mechanical...

Mechanical Engineering Industrial Visit to KEL Electrical Machines Limited, Kasaragod, Kerala

Industrial visits gives the students with an opportunity to learn practically through interaction,...

Mechanical Engineering Department Organized A Technical talk on “Numerical and Experimental Study of Passive Control of Ribs at Sonic and Supersonic Mach Numbers with Application of Neural Network”

The Department of Mechanical Engineering at Bearys Institute of Technology (BIT) Mangalore...

BIT, Mechanical Engineering Department Conducted “World Green Building Week-2023”

The Department of Mechanical Engineering successfully conducted “World Green Building Week” on...

PROJECT EXPO-2023

The Department of Mechanical Engineering at Bearys Institute of Technology (BIT) in Mangalore...

FAREWELL FUNCTION FOR THE BATCH 2019-23

Department of Mechanical Engineering organized a “FAREWELL FUNCTION” for 2019-23 batch students at...

Mechanical Engg

Two day Workshop on “The Indian Startup and MSME Ecosystem in the Age of AI” Concludes at Bearys Institute of Technology, Mangalore

Mangalore, December 5, 2024: The Department of Mechanical Engineering, Bearys Institute of...

Mechanical Engineering Department Organized a Talk on “My Constitution My Pride”

The Department of Mechanical Engineering at Bearys Institute of Technology (BIT), in association...

Inauguration of Mechanical Engineering Students Association (MESA 2K24-25) & Technical Talk

The Department of Mechanical Engineering inaugurated its student forum Mechanical Engineering...

Mohammed Humaid Wins Under-55 kg at VTU, to Represent University

At the VTU State Level Karate Competition 2024, Mohammed Humaid, a first-semester Mechanical...

Mechanical Engg. Industrial Visit to Lamina Foundries Limited, Udupi

Industrial visits allow the students to learn practically through interaction, working methods and...

Solar-Powered Lake Cleaning Boat Presented at International Jamboree

The Students of the Mechanical Engineering Department, Bearys Institute of Technology, Mangalore...

Python Programming – A 2-Day Workshop

The Department of Mechanical Engineering organized a two day workshop on “Python Programming for...

MoU sign up and a technical talk on “Advanced feature on Design and Digitization”

The Department of Mechanical Engineering organized MoU sign up and atechnical talk on “Advanced...

A technical talk on “Fundamentals and Applications of CFD in Aeronautical Engineering”

The Department of Mechanical Engineering organized a technical talk on “Fundamentals and...

ACHIEVEMENTS

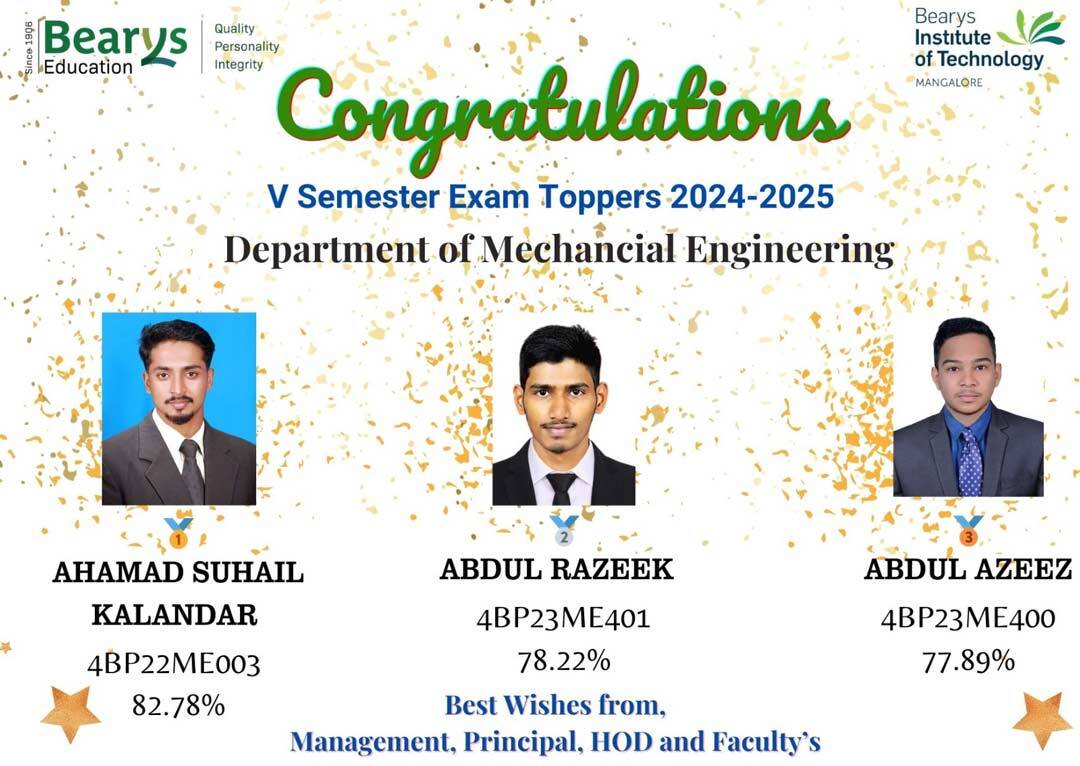

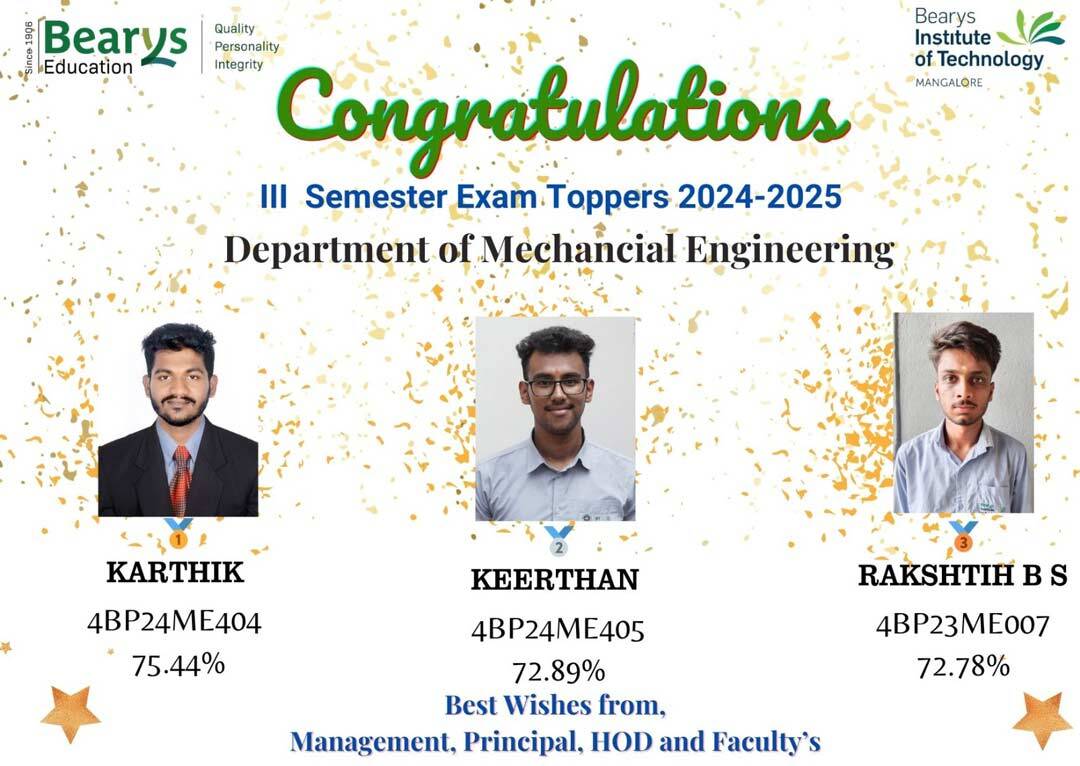

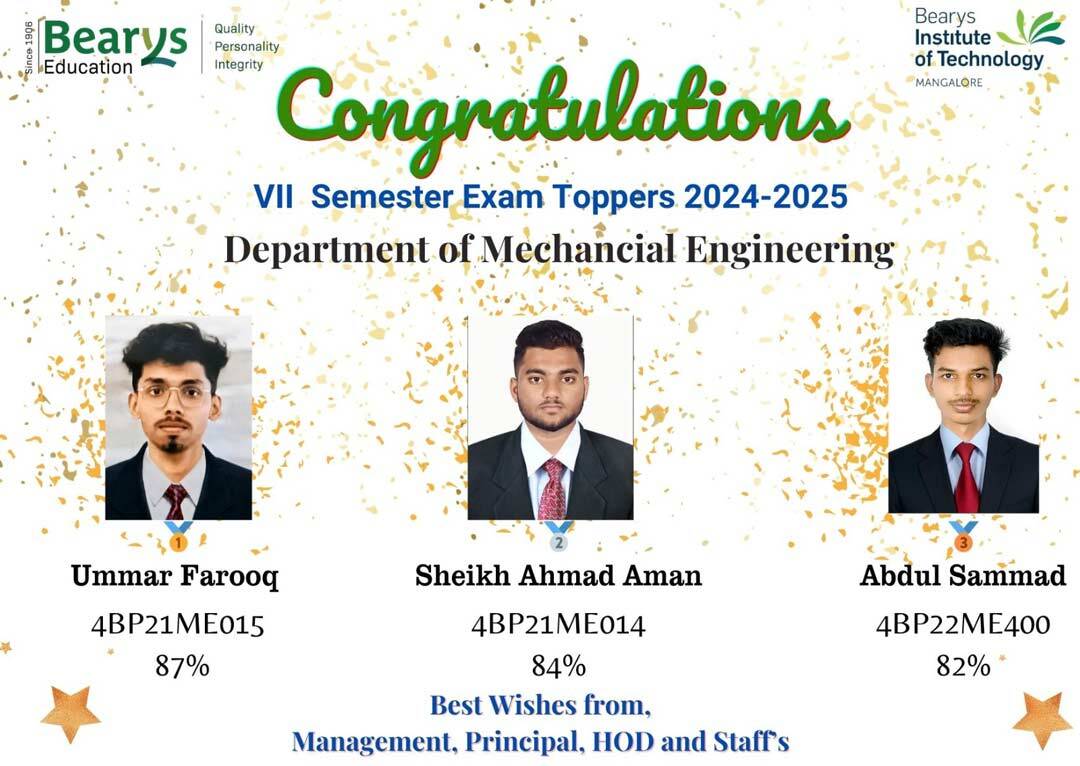

ODD SEM TOPPERS 2024-25

Two day Workshop on “The Indian Startup and MSME Ecosystem in the Age of AI” Concludes at Bearys Institute of Technology, Mangalore

Mangalore, December 5, 2024: The Department of Mechanical Engineering, Bearys Institute of...

“Studies on Mechanical and Tribological Behavior of ZA27/MoS2 Hybrid Composite”

Dr. Mohamed Kafeel Delvi, a faculty member in the Department of Mechanical Engineering at Bearys...

BIT Student Mohiuddin A.G Bags 7th Rank in VTU Exams

Mr. Mohiuddin A. G. of Bearys Institute of Technology (BIT) has secured the Seventh rank in...